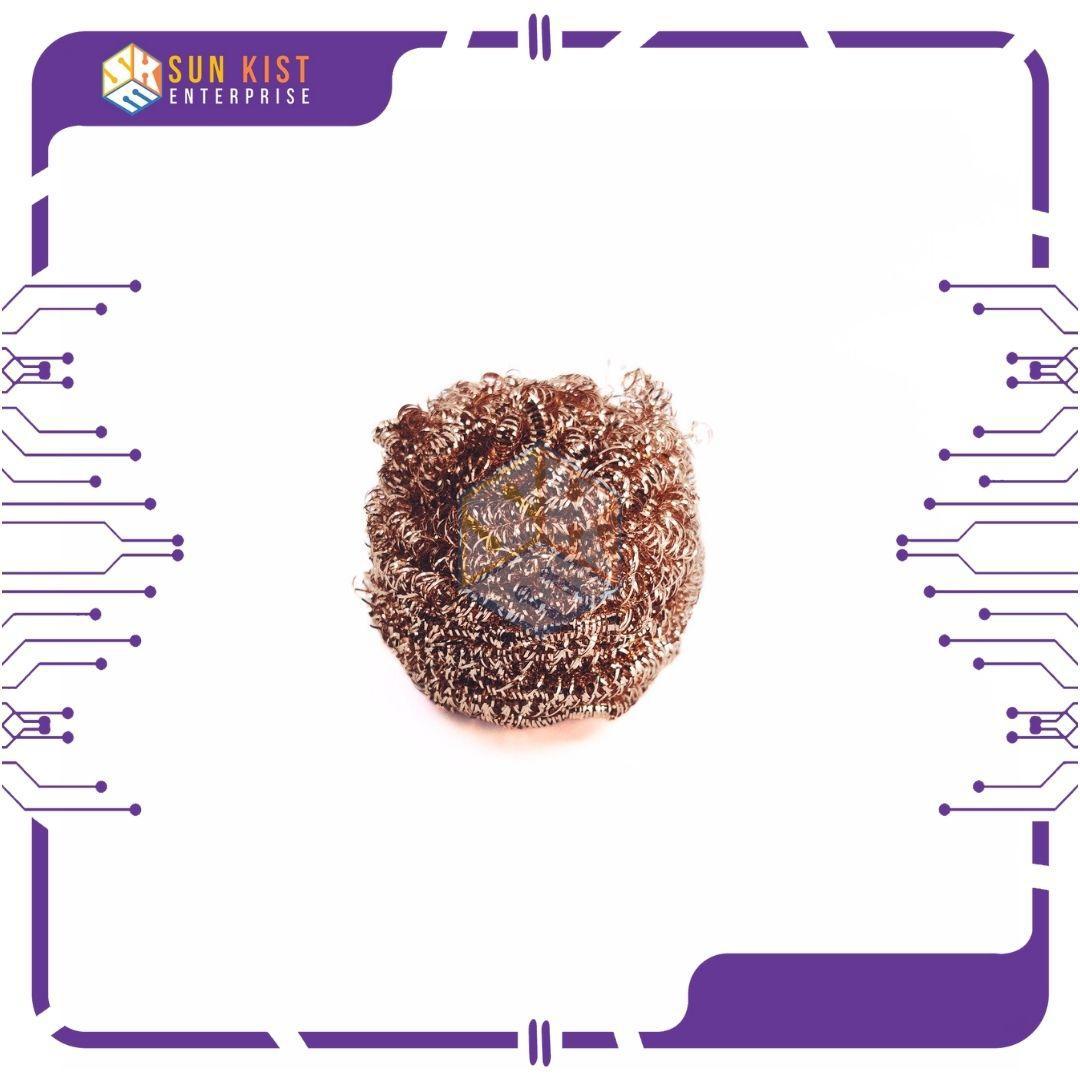

Description

A “Tip Cleaner Steel” is a tool used in soldering to clean the tip of a soldering iron. Keeping the soldering iron tip clean is important for maintaining good thermal conductivity and ensuring the quality of solder joints. The tip cleaner typically consists of a bundle of steel wires or other abrasive material housed in a container. Here are some key details about a typical tip cleaner steel:

1. **Material:**

– The cleaner is made of steel wires or another abrasive material that helps remove oxidation, solder residue, and other contaminants from the soldering iron tip.

2. **Container Design:**

– The cleaner is often housed in a container, which can be made of metal, ceramic, or other heat-resistant materials. The container provides a convenient and safe place to clean the soldering iron tip.

3. **Usage:**

– To clean the soldering iron tip, the user inserts the tip into the steel wires or abrasive material and rotates or moves the tip back and forth. This action helps remove any built-up solder, oxidation, or debris.

4. **Heat Resistance:**

– The materials used in the tip cleaner are chosen for their heat-resistant properties to withstand the high temperatures of the soldering iron tip.

5. **Non-Wetting:**

– The tip cleaner is designed to be non-wetting, meaning it does not introduce additional substances that can interfere with the soldering process.

6. **Longevity:**

– Tip cleaner steels are durable and can last for an extended period, depending on usage. Regular cleaning helps prolong the life of the soldering iron tip.

7. **Maintenance:**

– It’s important to periodically replace or replenish the tip cleaner if it becomes excessively dirty or worn.

8. **Portable:**

– Some tip cleaners are designed to be portable, allowing users to bring them to different workstations or project locations.

9. **No Water Required:**

– Unlike wet sponges used for tip cleaning, tip cleaner steels do not require water. They rely on the abrasive action of the steel wires to clean the tip.

Using a tip cleaner steel is a common practice in soldering, and it helps ensure that the soldering iron tip remains in good condition for efficient heat transfer and soldering work. It’s essential to follow the manufacturer’s guidelines for proper use and maintenance of the tip cleaner.